Diyi machinery is a subsidiary of Foshan Nanhai Mingyi packaging materials Co., Ltd. with years of accumulated industry experience, Diyi machinery is an innovative machinery manufacturing enterprise mainly engaged in the research and development, production, sales and service of aluminum profile automatic packaging equipment. Diyi machinery independently developed aluminum bagging machine, aluminum automatic film machine, aluminum coating machine, aluminum single binding bagging machine, aluminum automatic bagging machine, aluminum automatic packaging equipment, aluminum single bagging machine, aluminum film machine, aluminum automatic film machine, aluminum packaging equipment, aluminum automatic packaging machine, aluminum automatic film machine, Aluminum profile automatic packaging equipment, aluminum profile automatic packaging equipment and other main products have been favored by aluminum profile production and processing enterprises since they were put into the market. Especially, the single bar automatic bagging machine developed in the field of aluminum profile automatic packaging has provided a good solution for a series of "headache" problems such as the difficulty of recruitment.

To solve the industry pain point

——Automatic bagging machine for profile single binding

"This is the first single bar automatic bagging machine in profile packaging equipment." Mr. Liu said that the new equipment can use PE bags, PVC shrink film bags and other packaging materials, and various kinds of straight profiles such as aluminum multi bundle or combined bundle. In the control system, PLC integrated circuit, humanized touch screen, intelligent parameter setting, and "fool type" human-computer interaction interface are adopted. The profile materials with the length and width of 3000-7200 mm and 70-280 mm can be used, and the applicability is very strong.

"The problem of aluminum profile packaging is a pain point for most profile manufacturers. A bundle of aluminum materials weighs about 40 kg or 50 kg, which needs 2-3 people to complete the packing and bagging with the traditional manual packing method. Enterprises generally set up two shifts to work in turn. For workers, the labor intensity is high, 12 hours a day, and the work efficiency is difficult to guarantee. Uneven packing will cause poor quality. What's more, if the weight of a package is too heavy, it is easy to cause industrial accidents, which is really not worth the loss for the enterprise. "

Mr. Liu said that there are too many disadvantages in the traditional manual packing method. In recent years, with the gradual disappearance of the domestic demographic dividend period, the labor cost has been rising, and the disadvantages have been highlighted. The problem of human resources has reached a point that can not be ignored.

If this work only needs 2-3 people to complete, it is still within the scope of the enterprise. But for the whole production line, the number of packaging workers needed is far more than 2-3.

"For the whole packaging production line, packaging bagging is a process. After completion, it needs to be loaded and sent to the shrink film machine for processing. This is another process. The whole packaging process needs at least 6 people to complete."

From the perspective of the whole packaging production line, Mr. Liu once again stressed the importance and necessity of promoting the implementation of aluminum automatic packaging. In view of this problem, Diyi machinery as a one-stop aluminum packaging solution experts give the optimal solution.

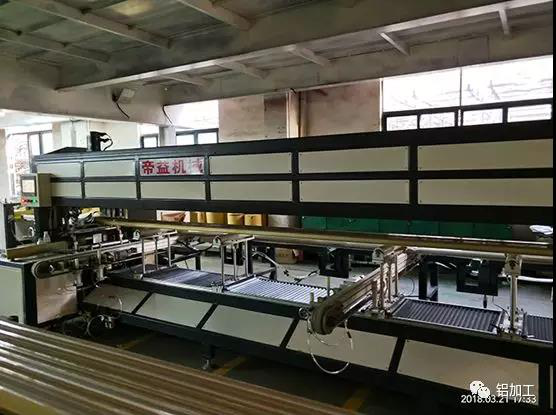

That is, since last year, after continuous debugging and optimization, Diyi machinery has been able to make a customized aluminum automatic bagging and packaging production line for the production workshop of the enterprise. From the schematic diagram given by President Liu, we can see that the whole production line is divided into 12 module groups, including feeding, feeding, automatic film cutting, automatic bagging, automatic discharging and other packaging processes.

Mr. Liu said, "the use of aluminum automatic bagging and packaging production line, saves the middle loading, unloading and other cumbersome links, only 1-2 people to operate, can complete the whole packaging process, compared with the traditional manual bagging efficiency increased by 4 times, labor cost effectively reduced by 40%."

It is understood that a packer's monthly salary fluctuates around 5000 yuan. According to the traditional packaging work mode of two shifts, the total labor cost has reached about 30000. The aluminum automatic bagging and packaging production line using Diyi machinery saves 5-6 people per shift, and saves hundreds of thousands of labor costs every year. This is a very considerable effect for an enterprise.

Automation is the trend

In fact, if you think about it in detail, is it really as simple as labor cost that automation machinery and equipment can save for a production enterprise? The answer is No.

Automation machinery and equipment to replace the traditional way of labor, save not only the wages of workers, but also the cost of enterprise management. It can be said that the automatic production improves the controllability of the production process, which is conducive to the timely and correct collection of production line data, so as to adjust more reasonable production planning and so on.

This is also the reason why Mr. Liu believes that it is the general trend for automation to replace labor in the future. No matter what industry, automation equipment is needed to solve the problem of labor cost. The market demand for automation machinery and equipment is increasing.

Of course, in order to better serve the profile enterprises, Diyi machinery has launched a series of packaging automation equipment, such as profile automatic film sticking, profile single piece automatic bagging machine, according to the packaging needs of customers.

At present, Diyi machinery has established cooperative relations with Xingfa aluminum, Huachang aluminum, Zhongya aluminum, Weiye aluminum, Aomei aluminum, Liaoshen aluminum, Haomen aluminum and many other domestic famous aluminum production enterprises.

In the future, I believe that under the trend of automation, Diyi machinery will usher in a broad space for development.

online service