Machine replacement is an important measure to promote the transformation and upgrading of traditional manufacturing industry. It is to upgrade traditional industries with modern and automated equipment, promote technology dividend to replace demographic dividend, and become the power source of new industrial optimization and upgrading and sustained economic growth. It is of great significance for technological progress, improving the quality of labor force, improving the production efficiency of enterprises, promoting the adjustment of industrial structure, and promoting the transformation of industrial development mode.

In fact, with the increase of labor cost and the sharp decrease of demographic dividend, the manufacturing industry, as a traditional industry, must face the problem of changing the mode of production and improving the ability of automation. Facing the same problems, the aluminum industry will usher in more fierce market competition. Among them, aluminum profile manufacturers pay more attention to promoting the transformation and upgrading of enterprises to automation and intelligence, and pay more attention to energy saving and consumption reduction, production efficiency improvement, cost reduction and other factors in the production process.

Seizing the market opportunity and turning crisis into opportunity, Diyi machinery is an innovative machinery manufacturing enterprise mainly engaged in R & D, production, sales and service of automatic packaging equipment for aluminum profiles. For many years, it has focused on R & D and production of automatic packaging equipment, and focused on solving the problems of high labor intensity and low efficiency of packaging workers, which has been widely praised by users.

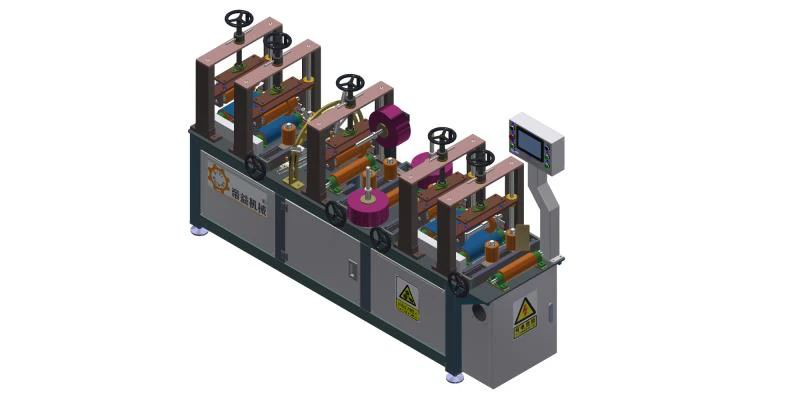

Diyi machinery automatic film sticking equipment

Specific performance features:

The main panel is finely ground by a large grinder to ensure the accuracy of the control panel.

Power, using two 3.0 kW servo motor drive.

The control system is composed of Mitsubishi PLC integrated circuit, infrared light sensor and other accessories, which can automatically locate the material position and cut the film in the process of film sticking.

In the process of laminating, by increasing the brush pressure film, the film is compact without bubbles, and the packaging quality of profiles is improved.

The material pasted with film is automatically transferred to the material assembling area through the auxiliary roller conveyor.

The biggest feature of the equipment is to save manpower in operation, one person can complete the film by operating the equipment independently, and the incision of the protective film is smooth without burr.

online service